Forklifts are an essential tool in many workplaces, but they can also be a source of danger if not operated correctly. Every year, workers suffer from forklift-related injuries due to negligence or lack of training. From sprains and strains to crushing injuries and even fatalities, these accidents can have serious consequences for both the worker and the organization.

In this blog post, we’ll explore some of the most common types of forklift-related injuries and how employers can prevent them from occurring on their premises. By understanding what causes such incidents and taking steps to mitigate potential risks, businesses can ensure that their staff remain safe while operating machinery like forklifts.

Overview of Forklift Injuries

Forklifts are powerful pieces of machinery and should never be operated without proper training.

Employers must take the necessary steps to ensure that their staff is properly trained and equipped with the right safety gear when operating forklifts.

According to a report by OSHA, forklifts result in 95,000 injuries and 100 deaths annually.

Most Common Forklift Injuries

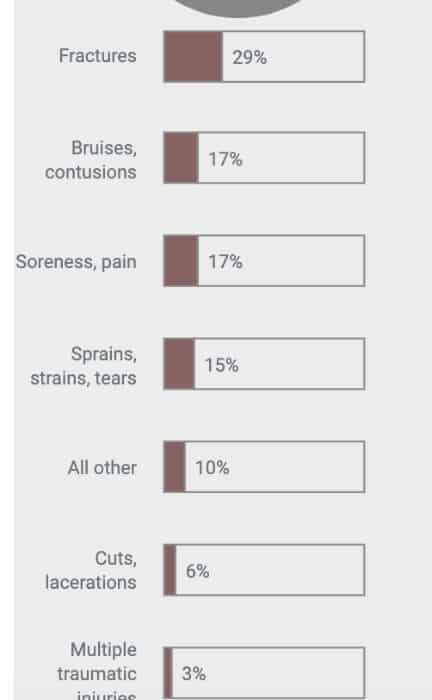

According to National Safety Council, the following are the most common injuries sustained on job sites with forklifts:

Fractures are the most common injury from operating a forklift with bruises, soreness, and sprains/strains all closely behind.

Types of Forklift Accidents Resulting in Injury

#1 Hitting or running over a pedestrian

According to the National Institute for Occupational Safety and Health (NIOSH), nearly 20 percent of forklift accidents involve a pedestrian, and 36% of deaths forklift-related deaths are pedestrians.

By ensuring that operators and pedestrians are provided with the necessary training, in addition to implementing safety solutions such as clear signage and floor tape, we will be able to significantly reduce this figure.

#2 Knocking Off a Pallet, Tipping or Damaging Racking

For those working at an elevated level, hoisting and lowering pallets can be a tricky task. Poor visibility significantly increases the risk of dropping the load, tipping it over, or causing damage to products or racking with forks.

This is not only a safety concern and cause for injuries to the forklift drivers but also to those around them. Resulting in head injuries, crush injuries, and even fatalities.

#3 Forklift Overturns: tipovers and rollovers

Forklift overturns are the number one cause of death related to lift trucks. These horrific events can occur due to:

- Improper turning

- Driving with an elevated load

- Excessive speed

By adhering to safe operating speeds and carrying capacities, avoiding abrupt turns, and ensuring proper maintenance of the forklift, employers can help reduce the risk of this occurring.

Strategies for Preventing Common Forklift-Related Injuries

Training

It’s essential that all operators receive proper training and are certified to operate the machinery safely. Employers must ensure that their staff is well-versed with the controls, surroundings, and hazards associated with lifting and maneuvering heavy loads.

Maintenance

Regular maintenance of forklifts is also necessary for ensuring safe working conditions. Operators should be trained to identify and report any wear, damage, or malfunction of the equipment.

In addition, employers should provide consistent maintenance of their forklifts and ensure they’re in good working condition at all times.

Final Thoughts on Keeping Workers Safe Around Machinery Like Forklifts

Forklifts are powerful pieces of machinery that can cause serious injury or even death if not operated properly. Employers must take the necessary steps to ensure their staff is well-trained and provided with the right safety gear when operating forklifts, as well as perform regular maintenance on them.

By understanding what causes such incidents and taking preventative measures, businesses can help keep their workers safe from harm while using heavy equipment like forklifts. With careful planning and implementation, employers will be able to create a workplace where employees feel secure in performing job tasks without fear of getting hurt due to improper operation of machines.

Contact WorkSafe to find out how we can help your company today!

Working to keep you safe, healthy, and productive,